- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

CMMEA Coconut methyl monoethanolamide CAS 371967-96-3

CMMEA Coconut methyl Monoethanolamide (CMMEA) is a plant derived non - ionic amide that has mild properties and easy biodegradation.

The following is a list of the most recent articles about Coconut methyl Monoethanolamide :

Surface activity

Coconut methyl monoethanolamide has excellent surface activity, which can form micelles in aqueous solution and reduce the surface tension of aqueous solution. This property makes coconut methylmonoethanolamide widely used in daily chemical products such as cleaning, shampooing, and bathing, which can produce rich foams and provide a good washing experience.

Thickening

Coconut methylmonoethanolamide also has thickening properties and can form a high-viscosity solution in an aqueous solution. This property allows coconut methylmonoethanolamide to be used as a thickening agent in personal care products such as shampoos, body washes, lotions, etc., to improve the consistency and texture of the product.

Stability

Coconut methylmonoethanolamide is stable in aqueous solutions and is not easy to hydrolyze and oxidize. Under normal storage and use conditions, the chemical properties of methyl monoethanolamide in coconut are relatively stable and do not easily deteriorate. This property makes coconut methylmonoethanolamide have a long shelf life and service life in daily chemical, food, pharmaceutical and other fields of products.

Natural sources

Coconut methylmonoethanolamide is a natural surfactant extracted from coconut oil, which has the advantages of natural, safe and environmental protection. Compared with the traditional chemical synthesis of surfactants, coconut methylmonoethanolamide is less irritating to the human body and has less impact on the environment, which meets the needs of modern people for green, healthy and environmental protection.

Biodegradability

Coconut methylmonoethanolamide can be degraded by microorganisms and will not cause long-term environmental pollution. This property makes coconut methylmonoethanolamide have less impact on the environment during production and use and meets the requirements of sustainable development.

Security

The safety of methyl monoethanolamide in coconut has been extensively studied and verified. In daily chemical products, the concentration of coconut methylmonoethanolamide is usually low and will not cause harm to the human body. At the same time, coconut methylmonoethanolamide does not contain harmful chemicals, is non-toxic and harmless to the human body, and is mild and non-irritating to the skin and hair.

Technical Parameter

Coconut methyl Monoethanolamide CMMEA

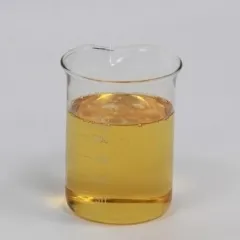

| Appearance | Odor | Amide content | Amine value (mgKOH/g) | pH(25,1%) |

| Light yellow transparent liquid | The smell of fatty acids is mild | >=96 | <=10.0 | <=10.0 |

Applications of Coconut methyl Monoethanolamide

:

Daily chemical industry

In daily use, coconut methyl monoethanolamide is mainly used to formulate personal care products such as shampoo, body wash, facial cleanser and lotion. Due to its excellent surface activity and thickening properties, coconut methylmonoethanolamide produces a rich and delicate foam that provides a gentle cleaning effect while giving the product a good texture. In addition, coconut methylmonoethanolamide has a certain moisturizing and moisturizing effect, which can improve the problem of dry and rough skin. Therefore, coconut methylmonoethanolamide is important in personal care products, meeting people's needs for gentle cleansing, moisturizing and natural health.

Food field

Coconut methylmonoethanolamide is mainly used to produce food additives and emulsifiers. Due to its natural origin and safety, coconut methylmonoethanolamide meets the standards and requirements for food additives. It can be used as a stabilizer, thickener, and taste improver in food to improve its taste and quality. For example, adding coconut methylmonoethanolamide to drinks can improve the taste and stability of the drink; Adding coconut methyl monoethanolamide to ice cream can improve the melting resistance and stability of ice cream. Therefore, coconut methylmonoethanolamide has a wide application prospect in the food industry.

Pharmaceutical field

In the pharmaceutical field, coconut methylmonoethanolamide is mainly used in drug preparation and delivery systems. Due to its excellent surface activity and thickening, coconut methylmonoethanolamide can be used as an emulsifier and suspension aid to increase the stability and solubility of drugs and improve their efficacy. At the same time, coconut methylmonoethanolamide can also be used as a carrier and coating material of drugs to control the release speed and targeting of drugs and to improve the bioavailability and therapeutic effect. Therefore, coconut methylmonoethanolamide also has a wide range of applications in drug preparation and drug delivery systems.

Production Method of Coconut methyl Monoethanolamide :

Raw material preparation: First, you must prepare coconut oil and ethanolamine (monoethanolamine, diethanolamine or triethanolamine). Coconut oil and ethanolamine are the main raw materials of this reaction.

Mixing: The coconut oil and ethanolamine are mixed in a certain ratio. Usually, the molar ratio of coconut oil to ethanolamine is between 1:1 and 1:3. The mass concentration of the mixture is generally between 40% and 60%.

Heating: The mixture is heated to a certain temperature, usually between 80 and 120 ° C. Heating can promote the reaction between coconut oil and ethanolamine.

Reaction: Under heating conditions, coconut oil and ethanolamine will react to form coconut methyl monoethanolamide. This reaction is reversible, and the molecular weight, viscosity, and other physical properties of the resulting coconut methylmonoethanolamide can be adjusted by controlling reaction conditions (such as temperature, pressure, time, etc.).

Cooling: The reaction mixture is cooled to room temperature so that the coconut methylmonoethanolamide crystallizes out.

Filtration: The precipitated coconut methylmonoethanolamide crystal is filtered out, and the excess unreacted ethanolamine and impurities are washed away with water.

Drying: The filtered coconut methylmonoethanolamide is dried by hot air or vacuum drying. The product obtained after drying is coconut methyl monoethanolamide.

Packaging: The dried coconut methylmonoethanolamide is packaged, generally stored and transported in bags or barrels.

Packing & Shipping of

Coconut methyl Monoethanolamide

:

There are many different types of packaging depending on the CMMEA Coconut methyl Monoethanolamide amount.

CMMEA Coconut methyl Monoethanolamide Packing

1kg/bottle. 25kg/barrel. 200kg/barrel.

CMMEA Coconut methyl Monoethanolamide Shipping:

As soon as payment is received, you can ship your order by air or sea.

Coconut monoethanolamide properties | |

| Alternative Names | N/A |

| CAS Number | 371967-96-3 |

| Compound Formula | RCON(CH3)CH2CH2OH |

| Molecular Mass | N/A |

| Appearance | Light yellow transparent liquid |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility In H2O | N/A |

| Exact Count | N/A |

| CMMEA Coconut methyl monethanolamide Safety & Health Information | |

| Sign Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Surfactant

MOA Polyethoxylated fatty alcohols CAS 9002-92-0

NEXT Surfactant