- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

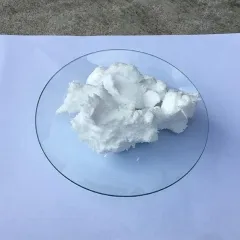

Polyglycol Stearate CAS 106-11-6

Polyglycol Stearate, a milky to solid paste is obtained through polymerization of stearic and ethylene oxide. Water solubility of PEG-6 stearate increases with increasing EO numbers.

Description of Polyglycol Stearate :

Hydrophilic and lipophilic balance: The polyethylene glycol stearate molecule contains polyethylene glycol (PEG) and stearic acid. The polyethylene glycol part has good hydrophilicity, while the stearic acid part has hydrophobicity. This balance of hydrophilic and hydrophobic makes polyethylene glycol stearate can be combined with water and oil simultaneously in the application, showing good emulsification, dispersion, wetting, and other properties.

Stability: Due to the combination of polyethylene glycol and stearic acid, polyethylene glycol stearate has good chemical stability at room temperature and is not easily hydrolyzed, oxidized, or subjected to other reactions. In addition, due to its hydrophilic and hydrophobic balance, polyethylene glycol stearate also has certain salt resistance, acid resistance, alkali resistance, and other properties and can maintain stability under different pH values and salt concentrations.

Wettability and permeability: Therefore, in cosmetics, pesticides, textiles, printing and dyeing, and metal processing, polyethylene glycol stearate is often used as a wetting agent, penetrant, and other additives, which helps the uniform dispersion and penetration of liquids.

Biocompatibility and biodegradability: Due to the good biocompatibility of the polyethylene glycol part, polyethylene glycol stearate has good biosafety in organisms. At the same time, polyethylene glycol stearate also has a certain biodegradability, which can be decomposed into harmless substances by microorganisms in the natural environment, reducing environmental pollution.

Rheological behavior: polyethylene glycol stearate can change the rheological properties of the system, and its rheological behavior can be controlled by adjusting the molecular weight and PEG chain length. This makes polyethylene glycol stearate important in preparing emulsion, foam, suspension and other systems.

Crystallinity: Due to the crystallinity of stearic acid, polyethylene glycol stearate also has certain crystalline properties. This crystalline property may be beneficial in some applications, such as in the preparation of microcapsules, drug delivery, etc., where its crystallinity can be controlled.

Surface activity: Polyethylene glycol stearate also has a certain surface activity due to its unique hydrophilic and lipophilic balance. It can be used as an emulsifier and dispersant to prepare emulsions, suspensions and other systems, contributing to liquids' stability and uniform dispersion.

Technical Parameter:

| Product Code | HLB | Appearance |

|---|---|---|

| Polyglycol Stearate | 18.8(SE-100) | Solidified milky paste |

Applications of Polyglycol Stearate:

Cosmetics industry: Polyethylene glycol stearate is mainly used as an emulsifier, wetting agent and thickener in cosmetics. It can reduce the interfacial tension of oil and water, improve the wettability and permeability of products, and make cosmetics more easily absorbed by the skin. At the same time, polyethylene glycol stearate also has certain antibacterial properties, which help maintain the hygiene and safety of cosmetics. In face cream, lotion, shampoo, body wash, and other cosmetics, polyethylene glycol stearate is widely used as the main ingredient or auxiliary ingredient.

Textile and printing industry: Polyethylene glycol stearate is mainly used as a softener, antistatic agent, and penetrant. It can improve the feel, gloss, and antistatic properties of the fabric, the printing and dyeing effect, and the quality of the fabric. At the same time, polyethylene glycol stearate can also be used as dyeing AIDS, fixing agents, etc., to improve dyes' coloring effect and durability.

Paints and coatings industry: Polyethylene glycol stearate is mainly used as a wetting agent, leveling agent and dispersant. It can improve the fluidity and leveling of the paint, improve the coverage and uniformity of the paint, and make the coating smoother, more uniform, and more beautiful. At the same time, polyethylene glycol stearate can also inhibit the settlement of pigments and fillers and extend the service life of coatings.

Pharmaceutical industry: Polyethylene glycol stearate can be used as a drug carrier, drug emulsifier, etc., to produce drugs. It can effectively disperse drug components uniformly in the medium and improve the stability and bioavailability of the drug. At the same time, polyethylene glycol stearate has lower toxicity and better biocompatibility, so it is also used in some medical devices and pharmaceutical excipients.

Agricultural field: In pesticides and fertilizers, polyethylene glycol stearate is mainly used as an emulsifier, wetting agent and thickening agent. It can improve the wettability and adhesion of pesticides, making it easier for pesticides to adhere to plant surfaces and play a role. At the same time, polyethylene glycol stearate can also improve fertilizer's solubility and permeability, improving fertilizer's utilization rate and absorption effect.

Production Method of Polyglycol Stearate:

Raw material preparation

Polyethylene glycol stearate includes stearic acid, polyethylene glycol, catalyst, and appropriate water. Among them, stearic acid provides the hydrophobic part; Polyethylene glycol provides the hydrophilic part; The catalyst is used to accelerate the reaction process;

Production steps

Esterification reaction: stearic acid and polyethylene glycol are esterified under a catalyst to produce polyethylene glycol stearate and by-product water. This step is the key to the entire production process, and it is necessary to control the conditions of the esterification reaction, such as temperature, pressure, reaction time, etc., to ensure the complete esterification reaction and the stability of the product.

Dehydration: The products obtained by esterification may contain unreacted stearic acid and water. Therefore, dehydration is required to remove excess water and unreacted stearic acid. This step usually uses heating, vacuum, or centrifugation to separate the water and the unreacted stearic acid from the product.

Refining and purification: The products obtained after dehydration may also contain some by-products and impurities. Therefore, refining and purification steps are required to improve the purity and stability of the product. This step typically removes impurities and by-products by filtration, recrystallization, or extraction.

Drying and packaging: The resulting polyethylene glycol stearate is dried and packaged for subsequent application. When drying, it is necessary to control the temperature and humidity to avoid degradation or caking of polyethylene glycol stearate. At the same time, it is also necessary to choose the appropriate drying method and equipment according to the actual situation to improve product quality and production efficiency.

Polyglycol Stearate Packing & Shipping

Polyglycol Stearate packaging is available in many different types.

Polyglycol Stearate Packaging

1kg/bottle. 25kg/barrel. 200kg/barrel.

Polyglycol Stearate shipping

As soon as payment is received, you can ship your order by air or sea.

Polyglycol Stearate Properties

| Alternative Names | PEG-n Stearate, Polyoxyethylene (n) monostearate |

| CAS Number | SG-2:106-11-6;SG-3:10233-24-6;SG-4:106-07-0;SG-6:10108-28-8;SG-8:70802-40-3;SG-9:5349-52-0;SG-14:10289-94-8;SE-100:19004-99-3 |

| Compound Formula | C18H20O3S*C6H15NO3 |

| Molecular Mass | N/A |

| Appearance | Milky paste solid |

| Density | N/A |

| Solubility In H2O | N/A |

| Exact Volume | N/A |

Polyglycol Stearate Safety & Security Information | |

| Sign Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Surfactant

PEG-150 Distearate CAS 9005-08-7

NEXT Surfactant