- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

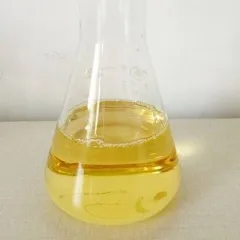

ODEA Oleic acid diethanolamide CAS 93-83-4

Oleic acid Diethanolamide exhibits excellent decontamination and emulsification. It also has foam stabilization properties, dispersion characteristics, solubilization properties, antistatic properties, lubrication qualities, corrosion inhibition, wear resistance, and foam stabilization.Active Matter Content: >=99.0

About ODEA Oleic acid diethanolamide :

First, oleic acid diethanolamine is a non-ionic surfactant with hydrophilic and lipophilic properties. Its molecular structure consists of two parts: one end is the oleic acid group, which is hydrophobic; the other end is the diethanolamine group, which is hydrophilic. This special molecular structure enables it to attract water and oil molecules in aqueous solution, reduce surface tension, and play a good role in emulsification, dispersion, wetting, etc.

Secondly, oleic acid diethanolamine has good stability. It can maintain good stability in weakly acidic and weakly alkaline media and is not easy to hydrolyze or oxidize. In addition, oleic acid diethanolamine also has a certain heat resistance, which is not easy to decompose or lose activity at high temperatures. This allows it to perform well over various temperatures and pH.

Thirdly, oleic acid diethanolamine has excellent wettability and permeability. It can effectively reduce the interfacial tension of oil and water, make oily substances better dispersed in water, and improve the wettability and permeability of the system. This makes oleic acid diethanolamine widely used in leather, textile, printing and dyeing, metal processing, and other fields as emulsifiers, wetting agents, softening agents, and other additives.

In addition, oleic acid diethanolamine also has certain antibacterial properties. In cosmetics, detergents, paints, and coatings, oleic acid diethanolamine can be used as a preservative or antibacterial agent to improve product health and safety performance.

Technical Parameters of ODEA Oleic diethanolamide

| Product Code | Shortname | Active material content | PH | Total amine value (mgKOH/g) | Appearance |

|---|---|---|---|---|---|

| Oleic acid diethanolamide | ODEA | 99% | 8.0~11.0 | <=40 | Amber transparent liquid |

Applications of ODEA Oleic acid diethanolamide :

Cosmetics industry: In cosmetics, oleic acid diethanolamine is mainly used as an emulsifier, wetting agent and thickening agent. It can reduce the interfacial tension of oil and water, improve the wettability and permeability of products, and make cosmetics more easily absorbed by the skin. At the same time, oleic acid diethanolamine also has certain antibacterial properties, which help maintain cosmetics' hygiene and safety. Oleic acid diethanolamine is widely used as the main ingredient or auxiliary ingredient in cosmetics such as face cream, lotion, shampoo, and body wash.

Textile and printing industry: In the textile and printing industry, oleic acid diethanolamine is mainly used as a softener, antistatic agent and penetrant. It can improve the feel, gloss, and antistatic properties of the fabric, the printing and dyeing effect, and the quality of the fabric. At the same time, oleic acid diethanolamine can also be used as dyeing AIDS, fixing agents, etc., to improve dyes' coloring effect and durability.

Paints and coatings industry: Oleic acid diethanolamine is mainly used as a wetting agent, leveling agent and dispersant. It can improve the fluidity and leveling of the paint, improve the coverage and uniformity of the paint, and make the coating smoother, more uniform, and more beautiful. At the same time, oleic acid diethanolamine can also inhibit the settlement of pigments and fillers and extend the service life of coatings.

Metal processing industry: In metal processing fluids, oleic acid diethanolamine is mainly used as an emulsifier, wetting agent and rust prevention agent. It can improve the wettability and lubricity of metal surfaces, reduce friction and wear, extend tool life and improve processing efficiency. At the same time, oleic acid diethanolamine can also inhibit metal corrosion and improve the anti-rust ability of metal surfaces.

Agriculture: In pesticides and fertilizers, oleic acid diethanolamine is mainly used as an emulsifier, wetting agent and thickening agent. It can improve the wettability and adhesion of pesticides, making it easier for pesticides to adhere to plant surfaces and play a role. At the same time, oleic acid diethanolamine can also improve fertilizer's solubility and permeability, improving fertilizer's utilization rate and absorption effect.

Production Method of ODEA Oleic acid diethanolamide :

Raw material preparation

The main raw materials needed for producing oleic acid diethanolamine include oleic acid, diethanolamine, catalyst, etc. Among them, oleic acid is an oleophilic group, providing hydrophobicity; Diethanolamine provides hydrophilicity. Catalysts are used to accelerate the reaction process.

Synthesis steps

Esterification reaction: Oleic acid and diethanolamine are esterified by a catalyst to produce oleic acid diethanolamide and by-product water. This step is the key to the entire production process, and it is necessary to control the conditions of the esterification reaction, such as temperature, pressure, reaction time, etc., to ensure the complete esterification reaction and the stability of the product.

Dehydration and refining: The products obtained by esterification may contain unreacted raw materials and by-product water. Therefore, dewatering and refining steps are required to remove impurities and obtain pure oleic acid diethanolamine. This step usually uses heating, vacuum, or centrifugation to separate the water and the unreacted raw material from the product.

Drying and packaging: The resulting oleic acid diethanolamine is dried and packaged for subsequent application. When drying, attention should be paid to controlling temperature and humidity to avoid degradation or caking of oleic acid diethanolamine. At the same time, it is also necessary to choose the appropriate drying method and equipment according to the actual situation to improve product quality and production efficiency.

ODEA Oleic diethanolamide packaging & shipping:

We offer a variety of packing options depending on ODEA Oleic Acid Diethanolamide quantities.

ODEA Oleic acid diethanolamide packing:

1kg/bottle. 25kg/barrel. 200kg/barrel.

ODEA Oleic acid diethanolamide shipping:

Payment receipt can be used to ship the goods by air, sea or express as soon as practicable.

ODEA Oleic acid diethanolamide Properties

| Alternative Names | Oleamide DEA |

| CAS Number | 93-83-4 |

| Compound Formula | C18H20O3S*C6H15NO3 |

| Molecular Mass | N/A |

| Appearance | Amber transparent liquid |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility In H2O | N/A |

| Exact Number | N/A |

ODEA Oleic acid diethanolamide Health & Safety Information | |

| Sign Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Surfactant

Sorbitan monooleate CAS 1338-43-8

NEXT Surfactant