- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

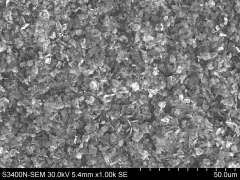

High Purity Graphite Powder Flake Graphite C Powder CAS 7782-42-5, 99.9%

Overview of Graphite Flake Powder :

Graphite sheet powder is a nanometer graphite material obtained from natural graphite after special processing. It is a great material with excellent chemical and physical properties. It is extensively employed in display, battery, semiconductors, and many other fields.

Graphite sheet powder has the following characteristics:

It has good electrical and thermal conductivity; its electrical conductivity is better than copper, and its thermal conductivity is better than diamond, which can effectively improve the performance and stability of electronic products.

With excellent mechanical properties, it can withstand extreme environments such as high temperature, high pressure, and high corrosion. It is widely used to manufacture high-performance composite materials and structural materials.

It has good chemical stability and does not easy to be oxidize, rust, and age, which can effectively improve the life and performance of batteries, catalysts, and other products.

With a low thermal expansion coefficient and excellent high-temperature resistance, it can effectively improve electronic products' high-temperature stability and reliability.

Features of Graphite Flake Powder :

Physical properties: Graphite powder has a soft texture, showing black and gray, and is easy to pollute the paper. Under the condition of isolation of oxygen, its melting point is above 3000 ° C, which is a very high-temperature resistant material. The thermal conductivity of graphite exceeds that of many metal materials, such as steel, iron, lead, etc. In addition, graphite also has good electrical conductivity, and its electrical conductivity is one hundred times higher than general non-metallic ores.

Chemical properties: Graphite has good chemical stability at room temperature and can resist the corrosion of acids, alkalis, and organic solvents.

Plasticity and lubricity: the toughness of graphite is good, and it can be made into a very thin sheet. At the same time, its lubrication performance depends on the size of the graphite flake; the larger the scale, the smaller the coefficient of friction, and the better the lubrication performance.

Other properties: Graphite also has good thermal shock resistance and can withstand drastic changes in temperature at room temperature without damage. In addition, graphite also has good electromagnetic properties, such as high permeability.

Advantages of Graphite Flake Powder :

High-temperature stability: graphite powder, in the isolation of oxygen conditions, with a melting point above 3000℃, is a very high-temperature resistant material. Therefore, it can work stably in high-temperature environments and is suitable for various high-temperature applications.

Good electrical and thermal conductivity: graphite powder has excellent electrical conductivity, which is one hundred times higher than general non-metallic ores. At the same time, its thermal conductivity is also more than many metal materials, such as steel, iron, lead, etc. This gives graphite powder in electronics, electrical appliances, communications, and other fields a wide range of applications.

Good lubricity: the lubrication performance of graphite powder depends on its scale; the larger the scale, the smaller the coefficient of friction, and the better the lubrication performance. Therefore, graphite powder can be used as a lubricating material to reduce mechanical wear and improve mechanical efficiency.

Plasticity: Graphite powder toughness is good, can be made into a very thin sheet, and is easy to process into various shapes. This gives the graphite powder great flexibility in manufacturing various graphite products.

Wide range of applications: Because graphite powder has the above advantages, it has many applications in many fields, such as refractory materials, conductive materials, lubricating materials, high-temperature metallurgical materials, polish and rust prevention agents.

Application of Graphite Flake Powder :

1. The battery field

Graphite sheet powder has good electrical and thermal conductivity, can be used as a negative electrode material of the battery, has high energy density and good cycle performance, and can effectively improve the capacity and life of the battery. In lithium-ion batteries, graphite sheet powder is particularly prominent as a negative electrode material, which will significantly increase battery capacity, as well as the cycle efficiency of the battery. In addition, graphite sheet powder can also be used as an electrolyte additive for the battery to improve the capacity and charge and discharge performance.

2. Display field

Graphite sheet powder has excellent mechanical properties and chemical stability and can be used as the cathode material of the display; with high emission efficiency and good thermal stability, it can effectively improve the brightness and reliability of the display. In fluorescent tubes, graphite sheet powder can be used as cathode material to improve the brightness and life of the lamp. In addition, graphite sheet powder may also be employed as an electrode in flat panel displays and OLED displays to improve the performance and stability of the display.

3. The semiconductor field

Graphite sheet powder has high thermal conductivity and good high-temperature resistance. It can be used as a heat sink and sealing material for semiconductor devices, effectively improving the performance and stability of semiconductor devices. In the semiconductor manufacturing process, graphite sheet powder is utilized as a supporting material for heat treatment materials and chemical vapor deposition substances to enhance the effectiveness and performance of semiconductors. In addition, graphite sheet powder can also be used as a packaging material for semiconductors to improve the reliability and stability of semiconductors.

4. Environmental protection

Graphite sheet powder has good chemical stability and corrosion resistance and can be used as a catalyst and adsorbent for environmental protection. In wastewater treatment, graphite sheet powder can be used as a catalyst to accelerate the wastewater treatment process and improve the purification effect of water quality. In air purification, graphite sheet powder can be used as an adsorbent to effectively remove harmful substances in the air.

5. Chemical industry

Graphite sheet powder has good wear resistance and corrosion resistance and can be used as a catalyst and carrier material in the chemical industry. In drug synthesis, graphite sheet powder can be used as a catalyst to improve the efficiency and purity of drug synthesis. In coatings, graphite sheets powder can be used as a carrier material to enhance the durability and resistance to corrosion of coatings.

Company Profile:

Synthetic Chemical is a trusted global chemical material supplier & manufacturer with over 12 years of experience providing super high-quality chemicals and nanomaterials, including boride powder, nitride powder, graphite powder, sulfide powder, 3D printing powder, etc.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory with advanced testing equipment, and an after-sales customer service center.

If you are looking for high-quality Graphite powder , please feel free to contact us or click on the needed products to send an inquiry.

Payment Term:

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment Term:

By sea, by air, by express, as customers request.

Storage Conditions:

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperatures.

3) Use immediately after opening the inner packing bag.

FAQ:

Q1:

What are the application areas of graphite sheets?

Chemical and pharmaceutical industry: Graphite sheets are used as catalyst carriers, fillers, and anti-corrosion materials in the chemical industry. In addition, graphite sheets also have good biocompatibility, so they are also used in the pharmaceutical industry to make medical devices and biological materials.

Graphite sheets can be treated at high temperatures in nanomaterials to produce graphene, a two-dimensional material with a single-layer thickness and excellent electronic, heat conduction, and mechanical properties. Graphene has many applications in nanomaterials, such as preparing high-performance transistors, flexible displays, and solar cells.

Thermal insulation field: Graphite sheet has low thermal conductivity and high-temperature stability, so they can be used as thermal insulation materials, such as building insulation materials, and high-temperature furnace insulation layers.

Q2:

Which areas are the most widely used graphite sheets?

Electronics industry: Graphite sheets are widely used as conductive materials in the electronics industry. Because graphite has good electrical conductivity, it is used to manufacture electrodes, connectors for electronic components, and so on. In addition, graphite sheets are also used to make heat sinks, such as heat sinks for computer cpus and Gpus, to improve the heat dissipation effect and ensure the stable operation of equipment.

Friction materials: Graphite sheet is widely used in friction materials because of its low friction coefficient. It makes brake linings, clutch plates, and motorcycle chains to reduce friction and wear between metal materials. With the rapid development of the transportation industry, the demand for friction materials is also increasing, so the application of graphite sheets in the field of friction materials is also very wide.

Q3:

What are the graphite sheets for industrial applications?

Graphite electrode: This is an important conductive material widely used in electric furnace smelting, casting, steel smelting, and other industries. Graphite electrode has high strength, high conductivity, and high-temperature stability.

Graphene: This two-dimensional material comprises a single layer of carbon atoms with excellent mechanical, electrical, and optical properties. Graphene has been widely used in electronic devices, energy storage, biosensing, and other fields.

Graphite-impregnated material: This is a kind of material with high temperature, high strength, and corrosion resistance, widely used in the chemical industry, metallurgy, machinery, and other fields.

Graphite heat exchanger: This is an important heat exchange equipment widely used in chemical, petroleum, electric power, and other fields. The graphite heat exchanger has good corrosion resistance, high-temperature stability, and high heat transfer efficiency.

Graphite seals: This is an important sealing material, widely used in chemical, petroleum, electric power, and other fields. The graphite seal has good corrosion resistance, high-temperature stability, and good sealing performance.

Q4:

What is the difference between natural graphite and artificial graphite?

They come from different sources. Natural graphite is an ore formed in the Earth's crust and obtained after mining and processing. Artificial graphite is obtained by high temperature and high-pressure treatment of carbon materials (such as graphite ore, coke, etc.) or chemical synthesis.

The structure of natural graphite is composed of carbon atoms arranged into a layered crystal structure, while the structure of artificial graphite can be in various forms, such as block, fiber, or powder. This structural difference makes them different in physical and chemical properties.

There are also differences between natural graphite and artificial graphite in the field of application. Natural graphite is often used in batteries, lubricants, graphite electrodes, and other fields, while artificial graphite is widely used in electronics, aerospace, chemical, composite materials, and other fields. The application of artificial graphite as a negative electrode material in lithium-ion batteries is one of its largest markets, which can greatly improve batteries' capacity and energy density. In addition, artificial graphite is also used to manufacture high-performance lubricants, friction materials, coatings, and so on.

Q5:

High-purity graphite powder?

High purity: The carbon content of high-purity graphite powder is very high, with almost no other impurities, so it has good chemical stability and physical properties.

High-temperature stability: High purity graphite powder has excellent high-temperature resistance, can maintain good stability and electrical conductivity at high temperatures, and is suitable for high-temperature environment applications.

Electrical conductivity: High-purity graphite powder has good electrical conductivity and is an excellent conductive material, widely used in electronics, electrical, communication, and other fields.

Lubrication properties: High-purity graphite powder has good lubrication properties and can be used to manufacture lubricants and coatings.

Corrosion resistance: High purity graphite powder has good corrosion resistance to acid, alkali, and other chemical substances and is suitable for the chemical industry, petroleum, and other fields.

Natural Flake Powder C Properties | |

| Alternative Names | Nature flake, flake, graphite |

| CAS Number | 7782-42-5 |

| Compound Formula | C |

| Molecular Mass | 12.01 |

| Appearance | Black solid |

| Melting Point | 3652 - 3697 degC (sublimes) |

| Boiling Point | 4200 degC |

| Density | 1.8 g/cm3 |

| Solubility (H2O) | N/A |

| Electrical Resistivity | N/A |

| Electronegativity | Paulings, 2.55 |

| Specific Heating | N/A |

| Thermal Conduction | 6.0 W/m-K |

| Thermal Expander | 4.9 um/m-K |

| Young's Module | 21 GPa |

| Exact Bulk | N/A |

| Heat of vaporization | At 4612 degC, 128 Kcal/gm of atoms are produced. |

Natural Flake Graphite POWDER C Health & Safety Information | |

| Safety Advisory | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us

PREVIOUS Elementary

High Purity Molybdenum Powder Mo Powder CAS 7439-98-7, 99.9%

NEXT Elementary