- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

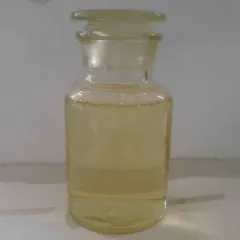

Penetrating agent

The main ingredient of Penetrating agent JFCU is C8-14 polyoxyethylene alcohol.Solid content (%):100

The following is a list of the most recent articles about

Penetrating agent JFC U

:

Permeability

The most remarkable property of a penetrant is its ability to penetrate. This property makes penetrants important in many processes, such as dyeing, printing, coating, cleaning, etc. By using penetrants, production efficiency and product quality can be effectively improved.

Wettability

Penetrants have good wettability, which can completely wet the solid surface with the liquid, forming a layer of lubricating liquid film. This property is very beneficial for improving product quality and production efficiency. For example, in metal processing, penetrants can effectively improve the wettability of the cutting fluid, thereby improving the cutting efficiency and machining quality of the workpiece surface.

Stability

The penetrant has good stability in different environments and conditions. It is not easy to react with other chemicals, nor is it easy to decompose and deteriorate. At the same time, the penetrant also has good heat and oxidation resistance and can maintain good stability at higher temperatures and in the presence of oxygen. This property allows the penetrant to maintain good performance during long-term use.

Low surface tension

This property makes the penetrant excellent in treating small gaps and holes, able to penetrate these difficult-to-wet areas easily.

Technical Parameter

Penetrating agent JFC U:

| Product Code | Cloud point | HLB | pH | Appearance |

|---|---|---|---|---|

| Penetrating agent JFC U | 40-50 | 11.5-12.5 | 5.0-7.0 | White paste can be made by converting milky liquid or transparent liquid into white paste |

Applications of Penetrating agent JFC U:

Textile printing and dyeing industry

In the textile printing and dyeing industry, penetrants are widely used in dyeing, printing, coating and cleaning processes. Through penetrants, the permeability and uniformity of dyes can be effectively improved, thereby improving the quality and efficiency of dyeing. At the same time, the penetrant can also be used as a softener, antistatic agent, etc., to improve the feel of the fabric, provide wrinkle resistance, and provide comfort.

Metal processing industry

In the metal processing industry, penetrants are mainly used in cutting fluids, cleaning agents and rust prevention agents. Through the use of penetrants, the wettability of the cutting fluid can be effectively improved, thus improving the cutting efficiency and the machining quality of the workpiece surface. At the same time, the penetrant can also be used as a cleaning agent, effectively removing the dirt and oil stains on the metal surface, and has a certain anti-rust effect.

Leather processing industry

In the leather processing industry, penetrants are mainly used for dyeing, finishing and waterproof treatment. By using penetrant, the permeability and uniformity of dye can be effectively improved, and the feel and appearance of leather can be improved. At the same time, penetrant can also be used as a finishing agent and waterproofing agent to improve leather's decorative and waterproof properties.

Water treatment industry

In the fields of sewage treatment and drinking water treatment, penetrants can be used to improve the efficiency and effectiveness of water treatment. For example, penetrants can be used as flocculants, dispersants, etc., to effectively remove suspended solids and impurities in water while also reducing water's surface tension and improving water's wettability and permeability.

Cosmetics industry

In cosmetics, penetrants are mainly used to formulate skin care products. Through penetrants, you can promote the penetration and absorption of nutrients and active substances and improve the effect on skin care. At the same time, penetrants can also be used as emulsifiers, thickeners, etc., to improve the texture and stability of skin care products.

Agriculture

In agriculture, penetrants can be used to prepare pesticides and fertilizers. Through penetrants, the permeability and adhesion of pesticides and fertilizers can be improved so that they are better attached to the plant's surface and penetrate the plant body to improve the use effect and efficiency of pesticides and fertilizers.

Production Method of Penetrating agent JFC U:

Chemical synthesis

Chemical synthesis is one of the main methods for producing penetrant. This method converts raw materials into penetrants through a series of chemical reactions. The following are the main steps of chemical synthesis:

Raw material preparation: Select the required raw materials, such as fatty acids, alcohols, catalysts, etc., and purify them to ensure the quality and purity of raw materials.

Esterification reaction: under the action of a catalyst, fatty acids and alcohols are esterified to produce corresponding ester compounds. This step is critical in the production of penetrant and requires control of reaction temperature, pressure and time to ensure that the esterification reaction is complete.

Refining and purification:

The esterification products are refined and purified.

The excess raw materials and by-products are removed.

A relatively pure penetrant is obtained.

This step can be separated and purified by distillation, extraction, recrystallization and other methods.

Through the above steps, different types of penetrants can be produced by chemical synthesis. It should be noted that chemical synthesis requires strict control of reaction conditions and raw material purity to ensure product quality and stability.

Natural extraction method

In addition to chemical synthesis, natural extraction can also be used to produce penetrants. The method uses the active ingredients in natural plants or minerals to extract and separate the penetrant. Here are the main steps of the natural extraction method:

Raw material selection: Select natural plants or minerals rich in the desired penetrant ingredients, such as seeds, fruits or roots of certain plants.

Extraction: The raw materials are properly treated, such as crushing, heating, soaking, etc., so that the active ingredients are fully dissolved in the solvent. Common solvents include water, ethanol, acetone, etc.

Separation and purification: through filtration, centrifugation, extraction, and other methods to separate and purify the active ingredients in the extract. This step can remove impurities and other components, creating a more pure penetrant.

The advantage of the natural extraction method is that it can use natural resources and avoid the environmental pollution problem of the chemical synthesis method. However, the production efficiency of the natural extraction method is relatively low, the cost is high, and the quality of raw materials and extraction conditions may affect the product quality and stability. Therefore, in actual production, choosing the appropriate production method according to the specific needs is necessary.

Packing & Shipping of

Penetrating agent JFC U

:

The packaging is dependent on the amount of JFC-U.

Penetrating agent JFC-U packing:

1kg per bottle, 25kg per barrel, or 200kg per barrel.

Penetrating agent JFC-U shipping:

After payment, you can ship your order by sea, air or express.

JFC U Properties

| Alternative Names | N/A |

| CAS Number | N/A |

| Compound Formula | N/A |

| Molecular Mass | N/A |

| Appearance | Transparent or milky fluid to white paste |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility In H2O | N/A |

| Exact Mass | N/A |

Health & Safety Information JFC-U Penetrating agent | |

| Sign Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Surfactant

ALES Ammonium laureth sulfate CAS 32612-48-9, 68%-72%

NEXT Surfactant