- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

High Purity Silicon Sulfide SiS2 Powder CAS 13759-10-9, 99.99%

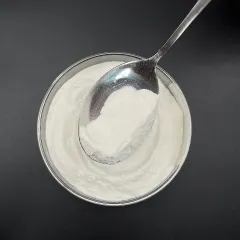

SiS2 is a molecular formula for silicon sulfide. The crystals of white fibrous orthorhombic and tetragonal crystals remain stable under normal pressure and temperature. Particle size: 100mesh

Purity: 99.99%

Product Name: Silicon Sulfide; silicon sulfide

Silicon Sulfide chemical formula: SiS2

Silicon Sulfide molecular weight: 92.21

Silicon Sulfide density: 1.853 g/cm3

Silicon Sulfide melting point: 1090

Silicon Sulfide boiling point: 1130

Silicon Sulfide CAS NO. : 13759-10-9

Silicon Sulfide Information:

SiS2 is a molecular formula for silicon sulfide. When moisture is present, white fibrous orthorhombic and tetragonal Crystals decompose to SiO2 and H2S. It is a flammable substance when heated.

Silicon Sulfide SiS2 Particles:

Silicon-sulfide, an inorganic chemical compound with a molecular formula of SiS2, is a colorless acicular crystal. SiS2 is a colorless, acicular crystal. Its relative density equals 2.02, its melting point is 1090, and at 1250, it sublimates to nitrogen. Insoluble in benzene; Soluble in dilute base. Hydrolysis and Ammonolysis were caused by water, ethanol, or liquid ammonia. The reaction of alkali metal sulfides with thiosilicates.

siS2 decomposes easily to produce hydrogen sulfide, just like other silicosulfide substances, such as bis (trimethylsilyl sulfides). It was reported that in liquid ammonia it can form the imide Si (NH)2 or NH4SH. Recent reports, however, have identified (NH4)2[SIS3(NH3)]*2NH3 containing the tetrahedral anion, SIS3(NH3).

By reaction with ethanol, tetraethyl and orthosilicate were produced. Alcoholysis was carried out with a large amount of tertbutyl ethanol to produce tri (tertbutyl) silicon mercaptan.

3 (CH3)3COH + Sis2 -[(CH3)3CO] 3Sish + H2S

Reaction of sodium sulfide with magnesium sulfide & aluminum sulfide gives sulphosilicate.

If you're interested in buying Silicon Sulfide, SiS2 powder at a bulk price, please send us an email to receive the most recent Silicon Sulfide pricing.

What is the production process of Silicon Sulfide (SiS2) Powder?

Direct synthesis method:

The direct synthesis method is the direct synthesis of silicon sulfide from silicon and sulfur under high temperatures and pressure. In this method, pure silicon and sulfur raw materials are usually heated to high temperatures (usually between 1000-1500 ° C) in a high-pressure furnace and kept in a sealed furnace chamber for some time to allow the silicon and sulfur to react to produce silicon sulfide. The resulting silicon sulfide particles are collected and processed to produce the desired product. This process can control the particle size, purity, and crystal structure of the product by controlling the heating rate, reaction time, and reaction atmosphere.

The advantage of this method is that it is simple and easy to obtain raw materials and is relatively cheap, so it has a low production cost. However, due to the conditions of high temperature and high pressure, the requirements for equipment and technology are high, and a strict quality control system is also required to ensure the quality and stability of products.

Chemical vapor deposition method:

Chemical vapor deposition (CVD) is a method of deposition and growth of silicon sulfide film on substrate by chemical reaction. In this method, a compound containing silicon and sulfur elements, such as silicon tetrachloride and sulfur vapor, is introduced into a high-temperature reaction chamber, where a chemical reaction occurs to produce silicon sulfide, which is deposited on the substrate. The structure, purity, and thickness of the deposited film can be controlled by controlling the reaction temperature, gas flow, and the position of the substrate.

The advantage of this method is that it can be carried out at normal temperature and pressure, which is suitable for large-scale production, and the deposited film has high quality and performance. However, due to the need to use high-temperature furnaces and precision-controlled equipment, the requirements for technology and equipment are high, and the production cost is also high.

Silicon Sulfide SiS2 SiS2 Powder

Silicon sulfide can be used as a source of silicon that is compatible with sulfates. Sulfate, also known as a sulfate ester, is formed when one or more hydrogens are replaced with metal.

Application of Silicon Sulfide (SiS2) Powder:

Polymer materials:

Silicon sulfide is a kind of polymer material with excellent thermal stability, corrosion resistance, and electrical properties, so it has a wide range of applications in the field of polymer materials. It can be used to manufacture polymer materials such as plastics, rubber, and coatings, which can improve the performance of these materials and improve their stability and durability. For example, adding silicon sulfide to rubber products can improve the hardness and temperature resistance of rubber.

Ceramic material:

Silicon sulfide is utilized to make ceramic materials. It is a great wear-resistant as well as high-temperature resistance and corrosion resistance. These properties will enhance the performance of the ceramic material. For example, in the manufacturing process of ceramic materials, the addition of silicon sulfide can increase the hardness and strength of ceramic materials, improving their wear resistance and high-temperature resistance.

Electronic and electrical fields:

Silicon sulfide also has a wide range of applications in electronic and electrical fields. It can be used to manufacture electronic components and electrical components that can improve their electrical properties and high-temperature resistance. For example, when manufacturing integrated circuits, adding silicon sulfide can improve their high-temperature resistance and electrical performance.

Catalyst field:

Silicon sulfide also has important applications in the field of catalysts. It can be used as a catalyst carrier to prepare a variety of catalysts. For example, in the petrochemical field, the addition of silicon sulfide can be used as a catalyst carrier to improve the activity and selectivity of the catalyst.

Glass and Optical Materials:

Silicon sulfide can be used to make glass and optical materials, which can improve their properties. For example, when making optical materials, adding silicon sulfide can improve their light transmission and chemical stability.

Storage condition of Silicon Sulfide (SiS2) Powder:

Silicon Sulfide SiS2 is affected by dampness, which will have an adverse effect on the performance of SiS2 powder and its use. Silicon Sulfide SiS2 must be packed in vacuum and kept in a room that's cool and dry. Silicon Sulfide SiS2 should not be exposed to stress.

Packing & Shipping Silicon Sulfide (SiS2) Powder:

The packing is dependent on the amount of Silicon Sulfide SiS2 POWDER.

Silicon Sulfide (SiS2) Powder packaging: vacuum packed, 100g,500g or 1kg/bag; 25kg/barrel. Or as per your request.

Silicon Sulfide SiS2 POWDER shipping: Could be shipped by air or sea as soon after payment receipt.

Synthetic Chemical Technology Co. Ltd.,is an established global chemical supplier and manufacturer, with over 12 years' experience in providing high-quality nanomaterials. These include boride powders, graphite or nitride particles, as well as sulfide or sulfide particles, for 3D printing.

We are happy to answer any questions you may have. (sales5@nanotrun.com)

Silicon Sulfide Properties | |

| Alternative Names | silicon(IV) sulfide, silicon disulfide, silicon(IV) sulphide, SiS2 powder |

| CAS Number | 13759-10-9 |

| Compound Formula | SiS2 |

| Molecular Mass | 92.22 |

| Appearance | White Powder |

| Melting Point | 1090 |

| Boiling Point | N/A |

| Density | 1.85-2.02 g/cm3 |

| Solubility In H2O | Decomposes |

| Exact Mass | 91.921068 |

Safety Information about Silicon Sulfide | |

| Sign Word | Danger |

| Hazard Statements | H261-H300-H315-H319-H335 |

| Hazard Codes | F. |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | UN3134 4.3.3+6.1/PG II |

Inquiry us

PREVIOUS Sulfide Powder

Chromium Sulfide Cr2S3 Powder CAS 12018-22-3, 99.99%

NEXT Sulfide Powder