- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

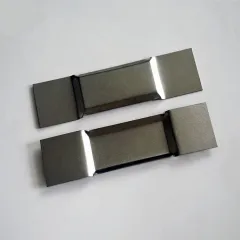

Metal Alloy High Purity Tungsten Boat Evaporation Boats of Tungsten

The tungsten boat is a type of tungsten vessel that looks like a boat. It can also be called the tungsten water boat, tungsten evaporation boats or coated tungsten boats. By high-temperature stamping, tungsten boat is made out of high-purity sheet.

About Metal Alloy High Purity Tungsten Boat Evaporation Boats Of Tungsten:

High strength and hardness: Tungsten is a high-strength and hardness metal with high tensile strength and yield strength. Therefore, the tungsten vaporization ship can withstand more significant pressure and bending stress and is not easy to deform or damage.

Good corrosion resistance: The tungsten vaporization ship is made of tungsten material and has good corrosion resistance. In the Marine environment, tungsten is not easily oxidized or corroded and can maintain the surface finish and beauty of the hull.

Good thermal conductivity: Tungsten is an excellent thermal conductivity material that can effectively dissipate heat. In the Marine environment, the tungsten vaporization ship can quickly conduct the heat inside the hull to the outside, reduce the temperature, and improve the hull's stability.

Good wear resistance: Tungsten is a high-hardness metal with good wear resistance. Therefore, the hull surface of the tungsten-vaporized ship is not easily worn or scratched, and the surface quality and beauty of the hull can be maintained.

Good processing performance: Tungsten is an easy-to-process material that can be made into various shapes and sizes of parts by casting, forging, welding, and other processing methods. Therefore, the tungsten vaporization ship can be made using different processing methods and performs well.

Good thermal insulation performance: Due to the high melting point of tungsten, the hull of the tungsten vaporization ship can be made into a double-layer structure, and the middle is filled with thermal insulation material, which has good thermal insulation performance. This reduces heat transfer from inside the hull to the outside, improving the stability and reliability of the hull.

Good impact resistance: Due to tungsten's high density and strength, tungsten vaporization ships have good impact resistance. In the Marine environment, tungsten vaporized ships can withstand more significant impact and vibration to ensure the stability and safety of the hull.

Environmental protection: The tungsten vaporization ship is made of tungsten material and does not contain substances harmful to the human body and the environment. At the same time, tungsten can be recycled and reused to reduce the waste of natural resources.

Application of Metal Alloy High Purity Tungsten Boat Evaporation Boats Of Tungsten:

Marine resources development: Tungsten vaporized ships can be used for Marine resources development, including seabed mineral resources seabed oil and gas exploitation. Due to its high strength, hardness, and good wear resistance, the tungsten vaporized ship can withstand various pressures and wear in the complex environment of the seabed and the mining process.

Marine scientific research: Tungsten vaporized ships can be used in Marine scientific research, including Marine geological surveys, biological research, Marine environmental protection, etc. Tungsten vaporized ships can provide a safe Marine test platform with good stability and heat insulation performance, ensuring experimental data's accuracy and reliability.

Marine transportation: Tungsten vaporization ships can be used for Marine transportation, including crude oil, chemicals, ores, and other goods. Due to the high strength, hardness, and good wear resistance of tungsten vaporized ships, they can withstand long-time transportation and complex Marine environments with good stability and safety.

Military field: Tungsten vaporized ship also has a wide range of applications in the military field, including the production of warships, submarines, and other water vehicles. Because tungsten vaporized ship has high strength, hardness, and good wear resistance, they can improve water vehicles' combat effectiveness and service life.

Entertainment field: Tungsten vaporized boats also have applications in the entertainment field, including producing luxury yachts and water sports boats. Due to its high strength, hardness, and good wear resistance, tungsten vaporized boats can provide a safe and comfortable aquatic entertainment experience.

Production Method of Metal Alloy High Purity Tungsten Boat Evaporation Boats Of Tungsten:

Raw material preparation: First, it is necessary to prepare high-purity tungsten powder or tungsten strips as raw material. The purity of tungsten powder should be higher than 99.9%, and the tungsten strip should be dense and homogeneous tungsten billet.

Mold preparation: Prepare the corresponding mold according to the shape and size of the tungsten vaporization ship required to be produced. The mold should have high strength, precision, and high-temperature resistance to ensure that the delivered tungsten vaporization ship meets the requirements.

Press forming: Tungsten powder or tungsten strip is put into the mold, and pressure is applied to press forming. The pressure should be kept uniform and stable during the pressing process to avoid problems such as cracks or pores.

Sintering: The pressed tungsten preform is put into the sintering furnace for sintering. The sintering temperature and time should be determined according to the material and performance requirements of the tungsten vaporization ship required to be produced to ensure the density and strength of the tungsten vaporization ship.

Processing: The sintered tungsten vaporizer ship needs to be processed to obtain the desired shape and size. Machining includes turning, milling, drilling, etc. During the processing process, the sharpness and accuracy of the processing tools should be maintained to avoid excessive stress or deformation.

Heat treatment: To further improve the corrosion resistance of tungsten vaporized ships, heat treatment is required. Heat treatment, including quenching, tempering, and other steps, can improve the grain structure of tungsten and enhance its hardness and wear resistance.

Polishing: The processed tungsten vaporizer needs to be polished to remove the burr and oxide on the surface and improve the finish and beauty of the character. Polishing can use mechanical polishing, chemical polishing, and other methods. It should be based on the required production of tungsten vaporization ship material and performance requirements to choose the appropriate polishing method.

Inspection: The final need to inspect the tungsten vaporization ship to ensure that it meets the quality requirements. Inspection includes appearance inspection, dimensional inspection, performance testing, etc., which can find and correct problems in production.

Payments & Transport:

Metal Alloy High Purity Tungsten Boat Evaporation Boats Of Tungsten Properties | |

| Other Titles | Tungsten Boat, Evaporation Boat of Tungsten |

| N/A | |

| Compound Formula | W |

| Molecular Weight | N/A |

| Appearance | N/A |

| Melting Point | N/A |

| Solubility In Water | N/A |

| Density | >=19.2g/cm3 |

| Purity | >=99.95% |

| Size | Individualized |

| Boling Point | N/A |

| Specific Heat | N/A |

| Thermo Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Module | N/A |

| Exact | N/A |

| Monoisotopic | N/A |

Metal Alloy High Purity Tungsten Boat Evaporation Boats Of Tungsten Health & Safety Information | |

| Safety Notice | N/A |

| Hazard Statements | N/A |

| Flashing Point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| RTECS # | N/A |

| Transport Information | N/A |

| Germany | N/A |

Inquiry us

PREVIOUS Metal Alloy

Metal Alloy High Purity Tungsten Wires High Temperature Heater Wire

NEXT Metal Alloy