- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

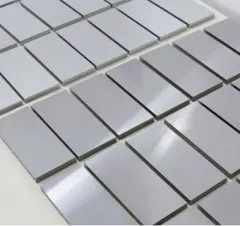

Metal Alloy 99.97% High Purity Polished Tungsten Plate

Polished Tungsten plate with 99.97% purity

About Metal alloy 99.97% high purity polished tungssten plate:

High purity: 99.97% high purity tungsten plate using high purity raw materials, after many purification and processing high purity. This high purity is conducive to improving tungsten plates' physical and chemical properties to meet the needs of various application fields.

Good mechanical properties: 99.97% high purity tungsten plate has high strength and hardness and can withstand high load and impact environment. In addition, tungsten plate also has good toughness, can absorb impact energy, and resist fracture. These mechanical properties make tungsten plates widely used in machinery manufacturing, aerospace, and other fields.

Good electrical conductivity: 99.97% high purity tungsten plate has good electrical conductivity and can meet the electrical requirements of electronic devices. In the electronics and semiconductor industry, tungsten plates are used to manufacture integrated circuit packages, chip carriers, etc., which can effectively transfer heat and improve the stability of electronic devices.

Good corrosion resistance: 99.97% high purity tungsten plate has good corrosion resistance in most chemical environments. In some acidic or alkaline media, tungsten plate can remain stable and not readily corrode or oxidize. This corrosion resistance makes tungsten plates widely used in chemical reactors, catalyst carriers, and other fields.

High-temperature performance: 99.97% high-purity tungsten plate has good high-temperature performance and can be stable in high-temperature environments. At high temperatures, the mechanical properties and electrical conductivity of tungsten plate are still excellent, making tungsten plate has a wide range of applications in aerospace, military, and other fields.

Good processing performance: 99.97% high purity tungsten plate has good processing performance and can be turned in milling, drilling, and other machining operations. These processing methods can adapt tungsten plates to different application needs and achieve customized production.

Production Method of Metal alloy 99.97% high purity polished tungssten plate:

Raw material preparation: First, it is necessary to prepare high-purity tungsten raw materials, usually using tungsten powder or tungsten strips as raw materials. These raw materials need to undergo a series of processing and treatment, such as crushing, mixing, pressing, etc., to prepare tungsten blanks of the required shape and size.

Pressing molding: the tungsten blank is put into the mold and pressed under a specific temperature and pressure to make a particular shape of the tungsten block. It is necessary to control the temperature and pressure during the pressing process to ensure the densification and shape stability of the tungsten billet.

Sintering: The pressed tungsten block is put into a high-temperature furnace so that the tungsten atoms reach densification, forming a plate with a particular strength. It is necessary to control the temperature and time during the sintering process to ensure the densification and stability of the tungsten plate.

Machining: The sintered tungsten plate needs to be machined, such as turning, milling, drilling, etc., to obtain the desired shape and size. In the machining process, it is necessary to control processing parameters, such as cutting speed, feed rate, etc., to ensure processing quality and accuracy.

Quality inspection: Quality inspection of the produced tungsten plate, including appearance inspection, size measurement, performance testing, etc. Only products that meet the quality standards can be considered qualified products. Otherwise, they need to be reworked or scrapped. Packaging: The eligible products will be packaged to protect the product's surface from contamination and damage. During the packaging process, it is necessary to pay attention to moisture, dust, and other measures to ensure the quality of products and safe transportation.

Applications of Metal alloy 99.97% high purity polished tungssten plate:

Electronics and semiconductor industry: In the electronics and semiconductor industry, 99.97% of high-purity tungsten plates are used to manufacture integrated circuit packages, chip carriers, radiators for electronic devices, etc. Tungsten plates can improve the stability and reliability of electronic devices and effectively transfer heat. In addition, tungsten plates can also be used to manufacture frames and reflectors for high-precision optical devices.

Aerospace industry: In the aerospace industry, 99.97% of high-purity tungsten plates manufacture high-temperature components, such as nozzles, combustion chambers, rocket engine parts, etc. Due to the excellent high-temperature performance, high strength, and wear resistance of tungsten plates, it can withstand high load and impact environments. In addition, tungsten plates can also be used to manufacture structural components of aircraft and reinforcement materials for body armor.

Military industry: In the military sector, 99.97% of high-purity tungsten plates are used to manufacture armor-piercing bullets, armor-piercing bullets, and other military equipment parts. Due to tungsten plates' high density, strength, and wear resistance, they can provide excellent armor penetration and impact resistance and maintain stability in high-speed impact environments. In addition, tungsten plates can also be used to manufacture armor plates for tanks and structural components for missiles.

Nuclear industry: In the nuclear sector, 99.97% of high-purity tungsten plates manufacture vital components such as control rods and fuel elements for nuclear reactors. Due to the corrosion resistance, excellent thermal conductivity, and high-temperature performance of tungsten plates, they can maintain stability in a nuclear radiation environment, control atomic reactions, and transfer heat. In addition, tungsten plates can also be used to manufacture catalyst carriers for chemical reactors.

Automotive industry: In the automotive sector, 99.97% of high-purity tungsten plates are used to manufacture automotive parts and spark plugs. Due to tungsten's excellent mechanical properties and durability, the container can withstand high temperatures and friction environments. In addition, tungsten plates can also be used to manufacture support frames and shock absorbers for automobile wheels.

Payments & Transport:

Tungsten Plate Properties 99.97% High Purity Metal Alloy | |

| Other Titles | Tungsten plate |

| N/A | |

| Compound Formula | W |

| Molecular Weight | N/A |

| Appearance | Plate |

| Melting Point | N/A |

| Solubility In Water | N/A |

| Density | N/A |

| Purity | 99.97% |

| Size | Individualized |

| Boling Point | N/A |

| Specific Heat | N/A |

| Thermo Conductivity | N/A |

| Thermal Expansion | N/A |

| Young’s Module | N/A |

| Exact | N/A |

| Monoisotopic | N/A |

Safety and Health Information | |

| Safety Notice | N/A |

| Hazard Statements | N/A |

| Flashing Point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| RTECS # | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us

PREVIOUS Metal Alloy

Metal Alloy High Temperature Inconel625 Alloy Rod

NEXT Metal Alloy