- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

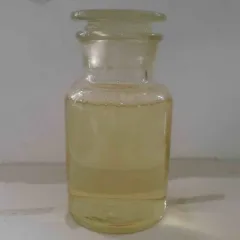

GlyceryI monooleate; GlyceryI oleate CAS 25496-72-4;111-03-5;68424-61-3

The chemical formula of glycerol monoleate (C21H40O4) is C21H40O4.

The following is a list of the most recent articles about Glyceryl Monooleate :

Surface activity

Glycerol monooleate has excellent surface activity, which can reduce the surface tension of water and form a stable and low interfacial tension foam. This property allows it to be used as a wetting agent, emulsifier, and dispersant in personal care products, pesticide sprays, the petroleum industry, and the food industry to improve substances' wetting, dispersing, and emulsifying properties.

Thickening

Glycerol monooleate has a good thickening effect and can significantly increase solution viscosity at low concentrations. This property makes it used as a thickener in products to regulate the consistency and texture of the product and improve the feeling of use.

Stability

Glycerol monooleate showed good stability over various pH values and temperature conditions. It is not susceptible to hydrolysis and oxidation deterioration and can remain stable in high-temperature and acidic environments.

Compatibility

Glycerol monooleate is compatible with other surfactants, fats, pigments, and other components and can be compatible with other components without precipitating or delamination. This property allows it to be used as a base ingredient in products such as cosmetics, food and pharmaceuticals to be combined with other ingredients to achieve better product results.

Biodegradability

This property has made glycerol monooleate an attractive surfactant choice for sustainable development under increasingly stringent environmental regulations.

Glyceryl monooleate: Technical Parameter

:

| Appearance | Active Matter Content(%) | HLB | |

| Light yellow liquid | N/A | N/A | 4.0 |

Applications of Glyceryl Monooleate

:

Personal care products

Glycerin monooleate is an important ingredient in personal care products, especially skin and hair care products. While also playing an antibacterial, anti-inflammatory and soothing role. Glycerin monooleate can be combined with other surfactants, oils and pigments to produce a variety of personal care products.

Pesticide spray

Glycerol monooleate is used as a wetting agent, emulsifier, and dispersant in pesticide sprays, which can improve the wetting, dispersing, and emulsifying properties of pesticides, make pesticides better attached to the surface of plants, and improve the utilization rate and control effect of pesticides. At the same time, the liquid medicine can better penetrate the back of the plant leaves to improve the control effect.

The petroleum industry

Glycerol monooleate is used as a wetting agent, emulsifier, and dispersant in the petroleum industry, which can improve oil recovery and crude oil processing efficiency. Glycerol monooleate can reduce the interfacial tension of oil and water so that crude oil can be better collected and processed. In addition, the glycerol monooleate can also improve the fluidity and stability of the oil and reduce its separation and precipitation.

Food industry

Glycerol monooleate is used in the food industry as a stabilizer, thickener, and emulsifier, which can improve the taste and quality of food. Glycerol monooleate can stabilize the oil and protein in food and prevent the separation and deterioration of food. At the same time, glycerin monooleate can also improve the viscosity and taste of food, making food more delicate and delicious. It is widely used in chocolate, ice cream and condiments.

Cosmetics

Glycerol monooleate is used as a thickener, stabilizer, and moisturizer in cosmetics, which can adjust the consistency and texture of products and improve their moisture and stability. Glycerin monooleate can be combined with other ingredients to produce a variety of cosmetics, such as creams, lotions, masks and lipsticks. It moisturizes the skin and enhances its gloss while acting as an antibacterial, anti-inflammatory, and soothing agent.

Medicine

Glycerol monooleate is used as a stabilizer, thickener, and lubricant in drugs, which can improve the stability and efficacy of drugs. The glycerin monooleate stabilizes the active ingredients in the drug, preventing their decomposition and deterioration. At the same time, glycerol monooleate can also improve the viscosity and lubricity of drugs so that they are better accepted and used by patients. In the pharmaceutical industry, it is widely used to prepare various drugs, such as tablets, capsules and suppositories.

Production Method of Glyceryl Monooleate :

Chemical synthesis

Chemical synthesis is the main method for the industrial production of glycerol monooleate. The method is usually based on raw materials such as glycerol, oleic acid, and catalysts, and glycerol monooleate is synthesized through a series of chemical reactions.

Raw material preparation: Glycerin can be refined by industrial-grade glycerin. Oleic acid is usually selected from natural plant or animal oleic acid, and the catalyst can be acidic or alkaline.

Esterification reaction: glycerol and oleic acid are esterified under the catalyst to produce glycerol monooleate. The esterification reaction is usually carried out at a certain temperature and pressure to promote the reaction. The selection of a catalyst greatly influences the efficiency and purity of the esterification reaction.

Separation and purification: The generated glycerol monooleate must be separated from the reaction liquid at the end of the reaction. Common separation methods include centrifugal separation, filtration, and extraction. After separation, the glycerol monooleate also needs to be refined and purified to remove the residual raw materials and catalysts to improve the purity and quality of the product.

Dry packaging: Finally, the final glycerol monooleate product is obtained after drying and packaging processes. Drying can use vacuum drying, spray drying, and other methods; packaging, generally in bags or bottles, is selected according to the requirements of the product.

Chemical synthesis has the advantages of mature technology, high yield, and low cost, so it is currently the main method of producing glycerol monooleate industrially. However, chemical synthesis requires the use of a large number of organic solvents and catalysts, which may cause some pollution to the environment. Therefore, it is necessary to pay attention to environmental protection issues in the production process and strengthen the treatment and utilization of wastewater and waste residues.

Biological fermentation method

Biological fermentation is another method of preparing glycerol monooleate, which converts glycerol into glycerol monooleate by microbial fermentation.

Strain selection and culture: The biological fermentation method must select microbial strains that produce glycerol monooleate, such as pseudomonas, yeast, etc. Under sterile conditions, the bacteria are inoculated into the medium for culture, providing suitable growth conditions such as temperature, pH value and nutrients, so the microorganisms multiply.

Fermentation: During microbial culture, various enzymes are secreted, including enzymes that catalyze glycerol conversion to monooleate. Under suitable conditions, these enzymes can convert glycerol into the target product glycerol monooleate. The fermentation process can be optimized by controlling temperature, pH, and stirring speed.

Separation and purification: The glycerol monooleate produced needs to be separated from the fermentation solution after fermentation. Common separation methods include centrifugal separation, filtration, and extraction. The separated glycerol monooleate must also be refined and purified to remove impurities and other microbial metabolites.

Dry packaging: Finally, the final glycerol monooleate product is obtained after drying and packaging processes. Drying can use vacuum drying, spray drying, and other methods; packaging, generally in bags or bottles, is selected according to the requirements of the product.

Packing & Shipping of GlyceryI monooleate

Glyceryl monooleate is available in a variety of different packagings.

Glyceryl monooleate packaging:

1kg/bottle. 25kg/barrel. 200kg/barrel.

Glyceryl monooleate Ethoxylates shipping:

Once payment has been received, goods can be sent by air, sea or express.

Glyceryl monooleate Properties

| Alternative Names | Glycerol Monoleate |

| CAS Number | 25496-72-4;111-03-5;68424-61-3 |

| Compound Formula | N/A |

| Molecular Mass | N/A |

| Appearance | Light yellow liquid |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility In H2O | N/A |

| Exact Mass | N/A |

| Glyceryl monooleate Health & Safety Information | |

| Sign Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Declarations | N/A |

| Transport Information | N/A |

Inquiry us

PREVIOUS Surfactant

GMS Glyceryl monostearate CAS 31566-31-1

NEXT Surfactant