- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

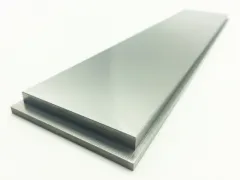

Metal Alloy High Purity 99.95% Tungsten Targets

Description of Tungsten Targets:

High density: Tungsten targets are very high, usually close to 19.3g/cm³. This high density gives tungsten targets good stability in the manufacturing process and can provide better weight distribution.

High melting point: The melting point of the tungsten target is very high, reaching 3410℃. This means that tungsten targets can maintain their structural stability at high temperatures and can, therefore, be used to manufacture components and structures in high-temperature environments.

Good electrical conductivity: Tungsten targets have good electrical conductivity in electronic devices. In addition, due to its high melting point and good electrical conductivity, tungsten targets are also used to manufacture electrical contact and electrical contact components.

Corrosion resistance: Tungsten targets have good corrosion resistance in most chemical environments. Therefore, it can manufacture components and structures in the chemical industry, such as those in reactors and high-temperature furnaces.

Good mechanical properties: Tungsten target has good mechanical properties, including high strength, hardness, and toughness. These characteristics enable tungsten targets to perform well in high loads and shock environments.

High hardness: Tungsten targets have high hardness and can resist wear and scratches during manufacturing. This hardness makes the tungsten target durable in the manufacturing process.

Good thermal stability: Tungsten target has good thermal stability at high temperatures, which can maintain the strength of its structure and performance. This means that tungsten targets can be used to manufacture components and systems in high-temperature environments without deformation or degradation of performance.

Good fatigue resistance: Tungsten target has good resistance and can withstand periodic and impact loads. This property makes tungsten targets have good durability and reliability in manufacturing.

Good plasticity: Tungsten target has good plasticity and can change its shape and size by plastic deformation. This property gives the tungsten target good machinability and adaptability in manufacturing.

Applications of Tungsten Targets:

Aerospace field: Tungsten target has a wide range of applications in the aerospace field. Due to its high density, high melting point, and good electrical conductivity, tungsten targets manufacturing various components and structures in aerospace spacecraft, such as fuel injectors, guide blades, turbine blades, and rocket nozzles. In addition, tungsten targets can also be used to manufacture high-temperature furnaces in aerospace spacecraft and components in reactors.

Electronics: Tungsten targets are also widely used in the field of electronics. Due to its high conductivity and melting point, tungsten targets are used to manufacture various components in electronic devices, such as resistors, capacitors, and tubes. In addition, tungsten targets can also be used to simulate multiple electronic devices, such as transistors and integrated circuits.

Nuclear industry: Tungsten targets are also widely used in the nuclear industry. Due to their excellent corrosion and high-temperature oxidation resistance, tungsten targets manufacture components and structures in atomic reactors, such as fuel rods, control rods, and reactor vessels. In addition, tungsten targets can also be used to manufacture other components and structures in the nuclear industry, such as components in nuclear fuel cycle systems.

Automotive field: Tungsten target is also widely used in the automotive field. Due to its high strength, hardness, and toughness, tungsten targets are used to manufacture various components and structures in automotive parts, such as valves, pistons, and crankshafts. In addition, tungsten targets can also be used to manufacture components such as car bodies and interiors.

Medical field: Tungsten targets are also widely used in the medical field. Due to its high density, good biocompatibility, and corrosion resistance, tungsten targets manufacturing various components and structures in medical devices, such as orthopedic implants, dental implants, and cardiovascular implants.

Production Method of Tungsten Targets:

Powder metallurgy: Powder metallurgy is a standard method for producing tungsten targets. This method makes tungsten powder into tungsten blank by pressing, sintering, processing, and then further processing and heat treatment. The advantage of powder metallurgy is that it can obtain high-density, high-strength, and corrosion-resistant tungsten targets, but the production cycle is longer, and the cost is higher.

Smelting method: The smelting method is another method of producing tungsten targets. The technique is to melt the raw material into a high-temperature furnace and then make a tungsten target through pouring, cooling, and processing. The smelting method has the advantages of a short production cycle and low cost, but obtaining tungsten targets with high density, high strength, and corrosion resistance is challenging.

Mechanical alloying method: The mechanical alloying method is a new method of producing tungsten targets. The technique is to mix tungsten powder with an appropriate amount of alloying elements and then through ball milling, pressing, and sintering to make tungsten billet, and then further processing and heat treatment. The advantages of mechanical alloying are that high-density, high-strength, and corrosion-resistant tungsten targets can be obtained, while the production cycle is short and the cost is low.

Chemical vapor deposition method: The method is to deposit tungsten compound vapor on the substrate through a chemical reaction at high temperature to form tungsten film, and then further processing and heat treatment. The advantage of chemical vapor deposition is that tungsten targets with high purity and ultra-fine particles can be obtained. Still, the production cycle is long, and the cost is high.

Payments & Transport:

Heavy Purity High Purity Metal Alloys 99.95% Tungsten Targets Properties | |

| Other Titles | Tungsten Target |

| N/A | |

| Compound Formula | W |

| Molecular Weight | N/A |

| Appearance | N/A |

| Melting Point | N/A |

| Solubility In Water | N/A |

| Density | >=19.15g/cm3 |

| Purity | >=99.95% |

| Size | Individualized |

| Boling Point | N/A |

| Specific Heat | N/A |

| Thermo Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Module | N/A |

| Exact Mass | N/A |

| Monoisotopic | N/A |

Heavy Purity Metal Alloy 99.95% Tungsten Focuses on Health & Safety | |

| Safety Notice | N/A |

| Hazard Statements | N/A |

| Flashing Point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| RTECS # | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us

PREVIOUS Metal Alloy

Metal Alloy 99.95% Purity Molybdenum Wires

NEXT Metal Alloy