- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- Cladding of metals

- News

- Blog

- Contact

- About

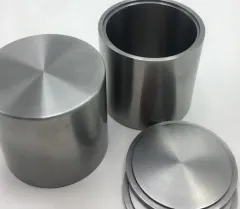

Metal Alloy 99.95% Purity Molybdenum Crucible High Heat Resistance

Made from pure molybdenum, this crucible has a 99.95% purity.

About Metal Alloy 99.95% purity Molybdenum crucible High Heat Resistance:

High purity: 99.95% molybdenum crucible has a very high purity, which means it contains deficient impurity elements, such as iron, carbon, etc. This high purity makes molybdenum crucible with excellent corrosion resistance and high-temperature properties.

High strength: The Molybdenum crucible has a high power, which makes it withstand more significant pressure and impact at high temperatures. As a result, it is not easily deformed or broken when handling molten metals and other high-temperature materials.

Good corrosion resistance: Molybdenum is a highly corrosion-resistant metal, so 99.95% molybdenum crucible has good corrosion resistance. It can be used in most chemical environments, including strong acids, bases, and salt solutions.

High-temperature performance: 99.95% molybdenum crucible has good high-temperature performance and can be used at extremely high temperatures. It has a melting point of about 2630 ° C, much higher than most other metals. Therefore, softening or dealing with high-temperature experiments and industrial applications is challenging.

Good thermal conductivity: Molybdenum is an excellent thermal conductivity material, so 99.95% molybdenum crucible has good thermal conductivity. It absorbs and dissipates heat quickly, making it more stable and controllable when handling molten metals and other high-temperature materials.

Easy to process: Molybdenum is an easy-to-process metal, so 99.95% molybdenum crucible can be made into different shapes and sizes of products through various processing methods. This makes it widely used in a variety of experimental and industrial applications.

Good oxidation resistance: Molybdenum cannot oxidize quickly at high temperatures, so 99.95% molybdenum crucible has good oxidation resistance. This allows it to maintain its original state in high-temperature experiments and industrial applications and is not affected by oxidation.

High repeatability: Due to the consistent physical and chemical properties of 99.95% molybdenum crucible, it can be reused in various experimental and industrial applications with reliable results.

Production Method Metal Alloy 99.95% purity Molybdenum crucible High Heat Resistance:

Raw material preparation: The raw material of the molybdenum crucible is a high-purity molybdenum rod or molybdenum powder. Before production, strict quality control should be carried out on raw materials to ensure their purity, strength, and chemical composition meet the requirements.

Mold preparation: Prepare the mold according to the shape and size of the required crucible. The mold material is generally alloy steel, resistant to high temperature and wear.

Ingredients and molding: use a molybdenum rod or molybdenum powder according to a certain proportion of ingredients, and thoroughly mix the appropriate amount of binder and lubricant into the mold. Then, the molybdenum crucible of the required shape and size is made by pressing, forming, and dressing.

Sintering: Put the molded molybdenum crucible into the sintering furnace for sintering treatment. The sintering temperature and time are determined according to the product requirements to make the molybdenum crucible have higher strength and corrosion resistance.

Heat treatment: The sintered molybdenum crucible must be heat treated to eliminate internal stress and improve performance. Heat treatment includes quenching, tempering, and other processes.

Surface treatment: After heat treatment, there may be an oxide layer or impurities on the surface of the molybdenum crucible, which needs surface treatment to remove the oxide layer, improve the surface quality, and improve its corrosion resistance and thermal conductivity.

Quality inspection: Quality inspection of the surface-treated molybdenum crucible, including appearance inspection, size inspection, performance testing, etc. Ensure product compliance with relevant standards and customer requirements.

Packaging and transportation: The qualified products are packaged to protect the molybdenum crucible from damage during transport. The packaging materials should be made of moisture-proof and shock-proof materials to ensure the safe delivery of products to customers.

Application of Metal Alloy 99.95% purity Molybdenum crucible High Heat Resistance:

Glass manufacturing: In the glass manufacturing industry, a 99.95% molybdenum crucible is widely used to manufacture various advanced glass products, such as optical glass, special glass, etc. Because molybdenum crucible has excellent high-temperature performance, it can meet the requirements of high-temperature melting and chemical reactions in glass manufacturing.

Ceramic industry: In the ceramic sector, 99.95% molybdenum crucible is used to prepare various high-performance ceramic materials. The molybdenum crucible's high-temperature performance and good thermal conductivity enable the ceramic material to maintain stable physical and chemical properties during the preparation process.

Metallurgy: In the field of metallurgy, 99.95% molybdenum crucible is used to extract and prepare various high-purity metal materials, such as tantalum, niobium, etc. Because molybdenum crucible has high purity, it can meet the metal material purity and quality requirements in the metallurgical process.

Chemical laboratory: In the chemical laboratory, a 99.95% molybdenum crucible is widely used in various high-temperature experiments and chemical reactions. Due to the high purity and stable chemical properties of molybdenum crucible, it can meet the requirements of various chemical experiments.

Aerospace: In the aerospace field, a 99.95% molybdenum crucible is used to prepare various high-performance aerospace materials, such as superalloys, titanium alloys and so on. Due to the excellent high-temperature performance and good corrosion resistance of molybdenum crucible, it can meet the strict requirements of material properties in aerospace.

Transportation & Payments:

Heavy Metal Alloy 99.95% High Purity Molybdenum crucible Excellent Heat Resistance Properties | |

| Other Titles | Molybdenum crucible |

| N/A | |

| Compound Formula | Mo |

| Molecular Weight | N/A |

| Appearance | Crucible |

| Melting Point | N/A |

| Solubility In Water | N/A |

| Density | 10.1g/cm3 |

| Purity | 99.95% |

| Particle Size | Individualized |

| Boling Point | N/A |

| Specific Heat | N/A |

| Thermo Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Module | N/A |

| Exact Mass | N/A |

| Monoisotopic | N/A |

Heavy Metal Alloy 99.95% High Purity Molybdenum - Crucible Heat Resistant Safety and Health Information | |

| Safety Notice | N/A |

| Hazard Statements | N/A |

| Flashing Point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety statements | N/A |

| RTECS # | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us

PREVIOUS Metal Alloy

Metal Alloy High Purity Molybdenum Crucible

NEXT Metal Alloy